Warehouse racking is central on the ingredient in successful storage management, letting enterprises to optimize space, boost accessibility, and boost efficiency within their services. With different racking methods obtainable, warehouses can correctly Arrange and store resources depending on their certain requires, from smaller conditions to bulk merchandise. Selecting the right racking process not merely maximizes storage potential but Furthermore makes sure worker basic safety and clean functions.

Forms of Warehouse Racking

A number of varieties of racking devices are generally used in warehouses, Each and every with exclusive benefits customized to different storage prerequisites:

Selective Pallet Racking: This may be the most Regular racking procedure, furnishing direct entry to each and every pallet. It’s really adaptable, which makes it suited to warehouses utilizing a high turnover of diversified solutions. Selective racking maximizes accessibility, Despite the fact that it may not be as space-effective as other programs.

Generate-In/Travel-By Racking: Created for large-density storage, travel-in racking makes it possible for forklifts to enter the racking program to hold and retrieve pallets. It’s appropriate for storing huge amounts of similar objects in a last-in, first-out (LIFO) program. Travel-by way of racking, alternatively, follows a first-in, very first-out (FIFO) technique and is additionally superb for pallet racking Brisbane stock rotation.

Cantilever Racking: Greatest suited to storing lengthy, bulky such things as pipes, lumber, and steel rods, cantilever racks provide open fronts that simplify loading and unloading. They in many cases are Employed in design and producing amenities where prolonged materials involve versatile storage.

Thrust Again Racking: This technique operates over the series of nested carts that roll along rails, letting pallets remaining stored two to 6 deep. It’s an effective, high-density Alternative for goods that don’t have to have instant retrieval, functioning with a LIFO technique.

Mezzanine Racking: By introducing another and in many cases third stage to some warehouse, mezzanine racking properly doubles or triples offered dwelling spot devoid of growing the dwelling by itself. This system is well suited for maximizing vertical House.

Great things about Productive Warehouse Racking

An economical racking process appreciably enhances warehouse operations by optimizing space utilization, improving access, and lessening retrieval situations. This leads to better inventory administration, as products are very easy to reach and organized, which minimizes labor expenses and increases efficiency.

Racking devices also promote basic safety by providing structured and stable storage. Correctly made racks lessen the likelihood of incidents, making sure a very good surroundings for both of those personnel and stock. Additionally, effectively-maintained racking systems lower hurt to saved products, improving inventory lifespan.

Choosing the Right Racking Procedure

Deciding upon the right racking method is determined by components like out there Place, inventory style, turnover charge, and funds. A radical assessment of storage needs and operational move works well for picking a racking technique that supports streamlined workflows and maximizes warehouse performance. Properly implemented, warehouse racking might be an financial commitment that takes treatment of in Room savings, safety, and long-term productivity.

Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Rachael Leigh Cook Then & Now!

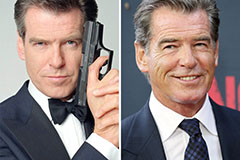

Rachael Leigh Cook Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!